Low-cost, clean heat.

At scale. For Industry.

A cleaner way to produce industrial heat.

CERTIFIED

POWER-TO-HEAT

> 93 % ENERGY EFFICIENCY

24/7 HEAT DISCHARGE

PLUG & PLAY

COST EFFECTIVE

ZERO EMISSIONS

25 YEAR LIFE

CERTIFIED

POWER-TO-HEAT

> 93 % ENERGY EFFICIENCY

24/7 HEAT DISCHARGE

PLUG & PLAY

COST EFFECTIVE

ZERO EMISSIONS

25 YEAR LIFE

CERTIFIED

POWER-TO-HEAT

> 93 % ENERGY EFFICIENCY

24/7 HEAT DISCHARGE

PLUG & PLAY

COST EFFECTIVE

ZERO EMISSIONS

25 YEAR LIFE

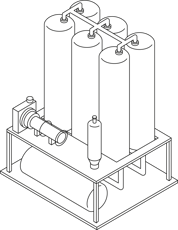

Our technology

Molten-salt thermal battery for efficient, high-temperature energy storage.

Learn more

Our impact

Made to decarbonize industries with process heat in the 150–300°C range.

Our product

Heatcube delivers low-cost, green steam on demand and at scale.

Learn moreTwo Heatcube delivery options

1. Heat-as-a-Service

Seamless, turnkey soluton

Kyoto removes complexity and financial risk, delivering a fully integrated Heatcube.

Fully managed by Kyoto Group

Kyoto oversees everything to ensure reliable operations, maintenance, and optimization.

Pay only for the steam you use

Supply of low-cost clean steam reducing both carbon emissions and energy costs.

2. Heat-as-a-Product

Delivered for ownership

Purchase a Heatcube — This model gives you asset ownership from day one.

Integrated into your operations

Kyoto ensures your Heatcube is seamlessly installed and configured to meet your specific industrial heat needs.

A sustainable investment

Owning a Heatcube is your investment in energy independence and long-term cost savings.

Low-cost heat

Heatcube supplies

clean, low-cost industrial

heat.

Heat without CO2

Reduces CO2 emissions annually by 2,000 to 15,000 tons.

On-demand heat

Absorbs surplus electricity and delivers heat exactly when you need it, 24/7.

Kyoto Group is addressing a crucial question on the agenda here in Germany and internationally: How to supply consistent industrial heat based on intermittent renewable energy sources instead of fossil fuels. We believe Heatcube is a very attractive answer to this question, and we very much look forward to working with Kyoto to realize its full potential.

Lutz Brandau, VP Sales of Steinmüller Engineering.

We have had a really good and instructive collaboration with Kyoto Group, and this is a good example of what we want to do with our new test centre - to develop and demonstrate new, groundbreaking and green technologies in collaboration with companies, researchers and authorities.

Søren Gais Kjeldsen, CEO of Aalborg Forsyning.

Our aim is to rely entirely on sustainable energy in the future while ensuring lower energy costs. Kyoto’s Heatcube will provide us with a stable and cost-effective supply of sustainable process heat, and we are excited to get started with this project.

Ádám Sass, Strategic Director of KALL Ingredients Kft.

We are proud of the smooth and successful introduction of the world’s largest electrical heater for molten salt and are looking forward to the large-scale commercial roll-out of Heatcube as well as the further development of the technology together with Kyoto Group.

Christopher Molnar, Managing Director of Vulcanic, a Spirax Sarco company

It is exciting to work together with the young and dynamic team of Kyoto and you can really feel the energy and the eagerness of the entire project team to contribute to a greener future. It gives me personally extra motivation for the entire project.

Magne Ryholt, Høglund Project Manager

The partnership with Kyoto and its Heatcube thermal storage solution is a further step for Iberdrola in its mission to decarbonize the economy through electrification. Storage is one of the major challenges in the energy transition, hence this collaboration with the Norwegian group will be key to our strategy

Fernando Mateo, Global Head of Industrial Decarbonization at Iberdrola

Kyoto Group is addressing a crucial question on the agenda here in Germany and internationally: How to supply consistent industrial heat based on intermittent renewable energy sources instead of fossil fuels. We believe Heatcube is a very attractive answer to this question, and we very much look forward to working with Kyoto to realize its full potential.

Lutz Brandau, VP Sales of Steinmüller Engineering.

We have had a really good and instructive collaboration with Kyoto Group, and this is a good example of what we want to do with our new test centre - to develop and demonstrate new, groundbreaking and green technologies in collaboration with companies, researchers and authorities.

Søren Gais Kjeldsen, CEO of Aalborg Forsyning.

Our aim is to rely entirely on sustainable energy in the future while ensuring lower energy costs. Kyoto’s Heatcube will provide us with a stable and cost-effective supply of sustainable process heat, and we are excited to get started with this project.

Ádám Sass, Strategic Director of KALL Ingredients Kft.

We are proud of the smooth and successful introduction of the world’s largest electrical heater for molten salt and are looking forward to the large-scale commercial roll-out of Heatcube as well as the further development of the technology together with Kyoto Group.

Christopher Molnar, Managing Director of Vulcanic, a Spirax Sarco company

It is exciting to work together with the young and dynamic team of Kyoto and you can really feel the energy and the eagerness of the entire project team to contribute to a greener future. It gives me personally extra motivation for the entire project.

Magne Ryholt, Høglund Project Manager

The partnership with Kyoto and its Heatcube thermal storage solution is a further step for Iberdrola in its mission to decarbonize the economy through electrification. Storage is one of the major challenges in the energy transition, hence this collaboration with the Norwegian group will be key to our strategy

Fernando Mateo, Global Head of Industrial Decarbonization at Iberdrola

Kyoto Group is addressing a crucial question on the agenda here in Germany and internationally: How to supply consistent industrial heat based on intermittent renewable energy sources instead of fossil fuels. We believe Heatcube is a very attractive answer to this question, and we very much look forward to working with Kyoto to realize its full potential.

Lutz Brandau, VP Sales of Steinmüller Engineering.

/01%20Homepage/1.6%20Partners%20logos/Energiaborze_logo_grey.png?width=112&height=112&name=Energiaborze_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/KALL%20Ingredients_grey.png?width=112&height=112&name=KALL%20Ingredients_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Kyotherm_300.png?width=112&height=112&name=Kyotherm_300.png)

/01%20Homepage/1.6%20Partners%20logos/steinmueller_engineering_company_logo_300.png?width=112&height=112&name=steinmueller_engineering_company_logo_300.png)

/01%20Homepage/1.6%20Partners%20logos/Cognite_logo_grey.png?width=112&height=112&name=Cognite_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Energiaborze_logo_grey.png?width=112&height=112&name=Energiaborze_logo_grey.png)

/01%20Homepage/1.6%20Partners%20logos/KALL%20Ingredients_grey.png?width=112&height=112&name=KALL%20Ingredients_grey.png)

/01%20Homepage/1.6%20Partners%20logos/Kyotherm_300.png?width=112&height=112&name=Kyotherm_300.png)

/01%20Homepage/1.6%20Partners%20logos/steinmueller_engineering_company_logo_300.png?width=112&height=112&name=steinmueller_engineering_company_logo_300.png)

/01%20Homepage/1.6%20Partners%20logos/Yara@2x.png?width=112&height=112&name=Yara@2x.png)

/01%20Homepage/1.6%20Partners%20logos/RPOW@2x.png?width=112&height=112&name=RPOW@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Aalborg-Forsyning@2x.png?width=112&height=112&name=Aalborg-Forsyning@2x.png)

/01%20Homepage/1.6%20Partners%20logos/AACSP@2x.png?width=112&height=112&name=AACSP@2x.png)

/01%20Homepage/1.6%20Partners%20logos/KTH@2x.png?width=112&height=112&name=KTH@2x.png)

/01%20Homepage/1.6%20Partners%20logos/Vulcanic.jpg?width=112&height=112&name=Vulcanic.jpg)

/01%20Homepage/1.6%20Partners%20logos/Cognite_logo_grey.png?width=112&height=112&name=Cognite_logo_grey.png)

Customer stories

Pioneering green heat in Europe

At the heart of Hungary’s agricultural sector, the next step in its energy transition is taking shape.

Heatcube #2 is being installed at KALL Ingredients — one of Europe’s most advanced grain processing plants.

Completion by summer 2025, the project marks a major leap toward fossil-free industrial heat, replacing gas with electrified thermal energy.

See how KALL Ingredients is leading the change.

Live from #1 Heatcube at Norbis Park

Completed in 2023

Latest news

EVENTS

KALL Ingredients Inauguration

The inauguration of our second European Heatcube at KALL Ingredients, Hungary.

Thermal Energy Day 2025

Meet the pioneering voices shaping the future of industrial heat

Sustainable Foods Summit 2025

Decarbonizing the Food industry with thermal energy